In the high-performance cycling world, where every gram and millimeter counts, JXD has carved a reputation as a trailblazer in CNC machined bike parts, specializing in lightweight, durable, and precision-engineered 6061-T6 aluminum bike components. As a leading bike parts manufacturer in China, JXD combines advanced CNC technology, material expertise, and a passion for cycling innovation to deliver solutions that redefine the boundaries of speed, comfort, and style.

The 6061-T6 aluminum alloy is a cornerstone of JXD’s product lineup, renowned for its exceptional strength-to-weight ratio, corrosion resistance, and machinability. This material allows JXD to craft bike components that are not only robust enough to withstand the rigors of competitive racing and off-road adventures but also lightweight enough to enhance agility and efficiency. From derailleur hangers and brake levers to stem adaptors and custom cockpit setups, JXD’s CNC-machined parts epitomize the fusion of form and function.

As a custom bike components manufacturer in China, JXD understands that cyclists and bike brands seek more than off-the-shelf solutions. The brand offers bespoke design and manufacturing services, allowing clients to create components tailored to their exact specifications. Whether it’s optimizing the geometry of a stem for aerodynamics, integrating brand logos or color schemes for marketing appeal, or developing proprietary mounting systems for accessories, JXD’s engineering team collaborates closely with customers to turn ideas into reality. This custom approach ensures that every component not only meets performance demands but also aligns with the bike’s aesthetic and brand identity.

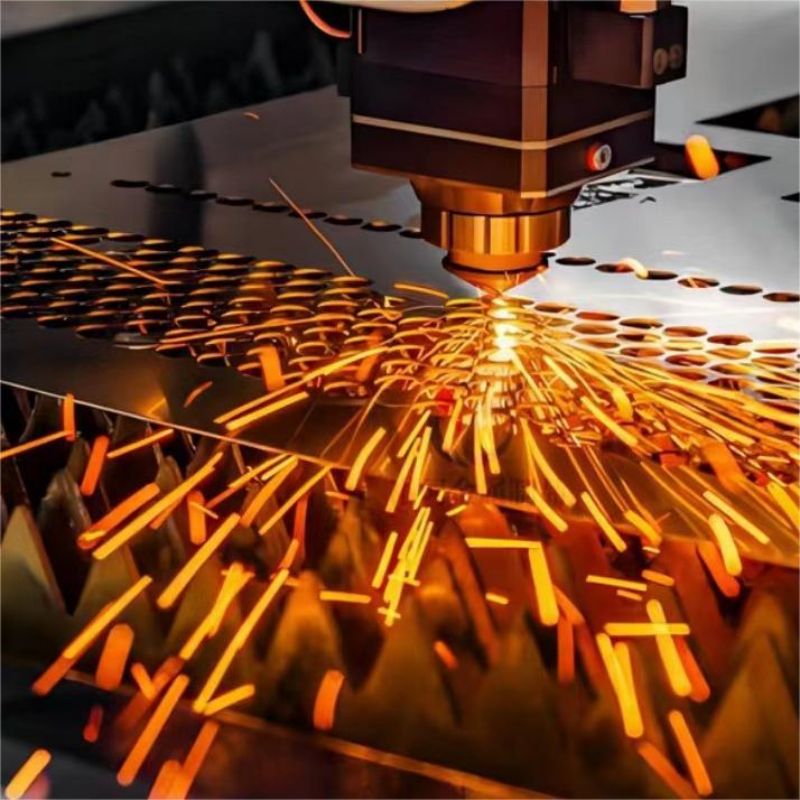

JXD’s strength lies in its state-of-the-art CNC machining capabilities. Based in China, the brand operates cutting-edge facilities equipped with multi-axis CNC mills, lathes, and finishing equipment, enabling it to achieve tolerances as tight as ±0.01mm. This precision ensures seamless fitment with other bike components, reduces vibrations, and enhances overall ride quality. Additionally, JXD’s in-house anodizing, powder coating, and laser etching services allow for vibrant color finishes, durable coatings, and brand customization without compromising structural integrity.

Quality control is paramount at JXD. The brand adheres to strict ISO 9001:2015 standards, with every component undergoing rigorous inspection at multiple stages of production. From raw material testing to dimensional checks and fatigue simulations, JXD leaves no stone unturned in ensuring its bike parts meet or exceed industry benchmarks.

Beyond manufacturing, JXD excels in customer collaboration. The brand’s engineers work closely with bike designers, professional cyclists, and aftermarket modifiers to understand evolving trends and demands. Whether it’s developing a prototype for a new frame design, refining an existing component for better ergonomics, or scaling production for a global brand, JXD’s flexible processes and quick turnaround times make it a trusted partner in the cycling ecosystem.

Sustainability is also at the forefront of JXD’s operations. The brand invests in eco-friendly machining practices, such as dry cutting techniques to reduce coolant waste, recycling aluminum scraps for re-melting, and optimizing packaging to minimize carbon footprints.

In conclusion, JXD is more than just a bike parts manufacturer—it’s a catalyst for cycling excellence. By blending its expertise in CNC machined bike parts with a deep commitment to customization and quality, JXD empowers cyclists, brands, and retailers to push the limits of performance and design. Whether you’re a professional racer seeking a competitive edge, a bike manufacturer looking for reliable OEM components, or an enthusiast seeking unique upgrades, JXD delivers precision, innovation, and reliability. Choose JXD—where CNC craftsmanship meets the passion of cycling, one component at a time.