In the competitive world of cycling, where every gram counts and aerodynamics define performance, CNC Bike Parts have become synonymous with cutting-edge engineering and craftsmanship. Among the elite CNC Machining Manufacturers, JXD emerges as a trailblazer, leveraging China’s manufacturing prowess to deliver bespoke, high-performance components that redefine the boundaries of two-wheeled excellence.

As a leading CNC Manufacturing Process Specialist in China, JXD specializes in transforming raw aluminum, titanium, and carbon fiber composites into intricate bike parts that balance strength, weight, and aesthetics. Unlike mass-produced alternatives, JXD’s CNC Bike Components are machined with micron-level accuracy, ensuring seamless integration with frames, drivetrains, and suspension systems. This precision has made JXD a trusted partner for professional racing teams, custom frame builders, and cycling enthusiasts who demand perfection.

What truly sets JXD apart is its unwavering focus on customization. Recognizing that every cyclist has unique needs—whether for competitive racing, long-distance touring, or urban commuting—the brand offers custom CNC bike components tailored to individual specifications. Clients can collaborate with JXD’s engineers to design derailleur hangers, brake levers, stem adapters, or even proprietary cockpit systems, all optimized for weight savings, stiffness, or ergonomic comfort. This bespoke approach has cemented JXD’s reputation as a collaborator, not just a supplier, for cyclists seeking a competitive edge.

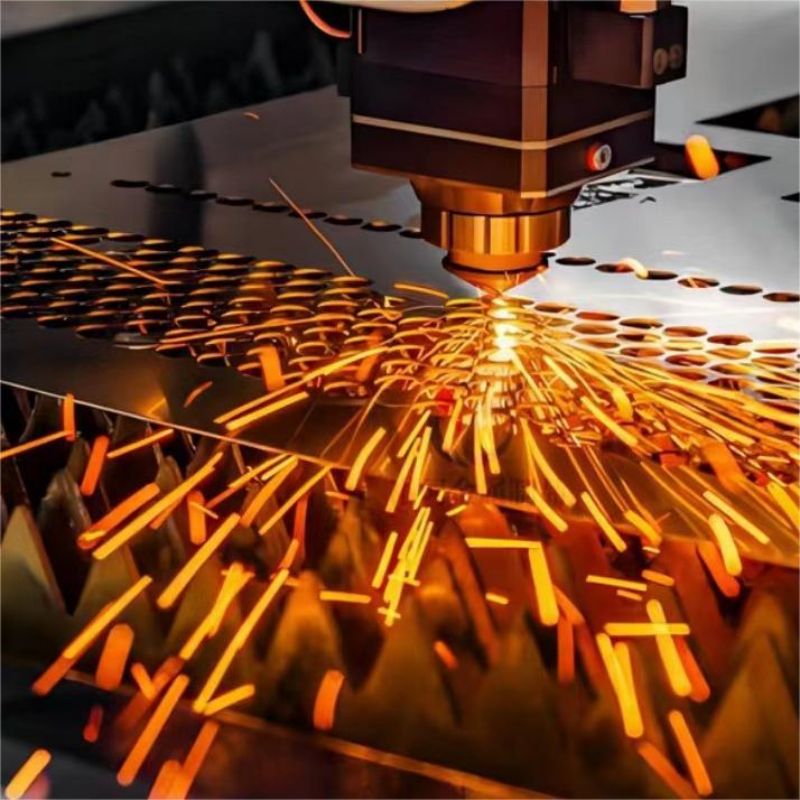

China’s manufacturing ecosystem provides JXD with unparalleled access to advanced CNC mills, lathes, and multi-axis machining centers, enabling the brand to tackle complex geometries with ease. The CNC manufacturing process at JXD involves rigorous quality control, from CAD design simulations to post-machining surface finishing, ensuring every part meets or exceeds industry standards. Additionally, the brand’s use of sustainable practices—such as recycling metal chips and minimizing energy consumption—aligns with modern cycling’s eco-conscious ethos.

Innovation is another cornerstone of JXD’s philosophy. By integrating additive manufacturing techniques with traditional CNC subtractive processes, the brand explores hybrid solutions that reduce material waste while enhancing part functionality. For example, JXD’s lightweight crank arms and chainrings combine CNC-machined cores with 3D-printed titanium lattices, offering unparalleled strength-to-weight ratios.

Beyond product excellence, JXD excels in customer-centric service. As a China-based manufacturer, the brand maintains a streamlined supply chain, enabling rapid prototyping and quick turnaround times for custom orders. Clients also benefit from JXD’s global network of distributors and technical support, ensuring seamless integration of components into any bike build.

For cyclists and manufacturers seeking to elevate their machinery, partnering with JXD means accessing a partner that combines Chinese manufacturing scale with artisanal precision. The brand’s ability to craft custom CNC bike components—backed by decades of aerospace and automotive CNC expertise—ensures parts that are not only race-ready but also a testament to human ingenuity. In an industry where innovation and personalization drive success, JXD’s solutions prove that CNC machining is the art of transforming metal into motion.