In industries where precision, corrosion resistance, and durability are non-negotiable—such as medical devices, aerospace, and food processing—the choice of materials and manufacturing processes can make or break a product. Enter JXD, a pioneering custom CNC machining manufacturer based in China, specializing in CNC machined SUS304 parts and precision stainless steel components that meet the most demanding global standards. With a focus on innovation, quality, and client-centric solutions, JXD has emerged as a trusted SUS304 stainless steel supplier for OEMs, engineers, and innovators worldwide.

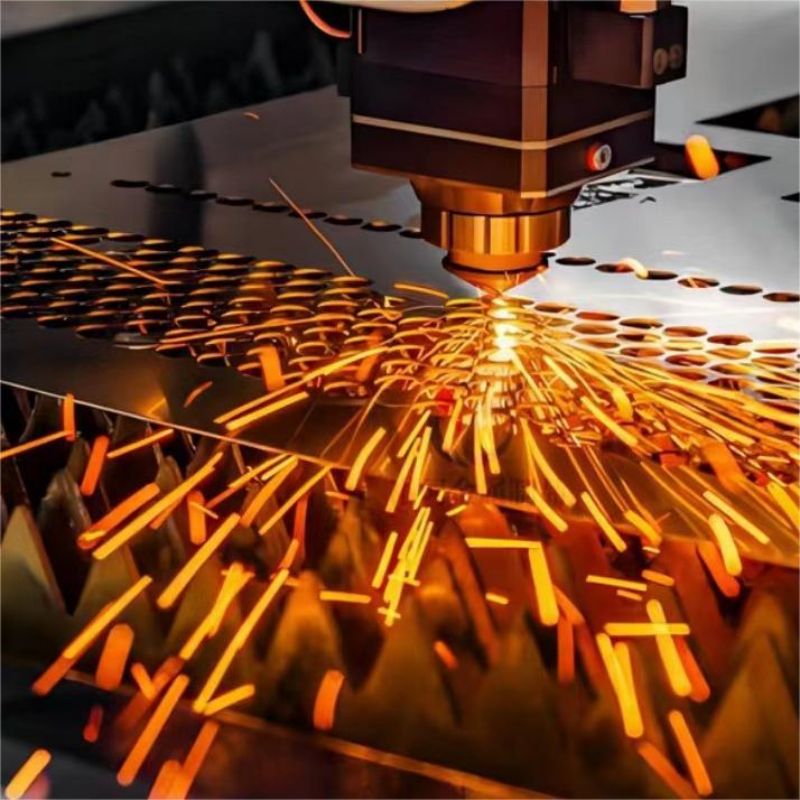

JXD’s expertise lies in transforming raw SUS304 stainless steel—a versatile, corrosion-resistant alloy with 18% chromium and 8% nickel—into high-precision components that perform flawlessly in harsh environments. The brand’s CNC machined SUS304 parts range from microscopic surgical instrument components to heavy-duty hydraulic fittings, all crafted with tolerances as tight as ±0.005mm. Using 5-axis CNC mills, Swiss-type lathes, and multi-spindle automatics, JXD ensures every part meets or exceeds ISO 9001 and AS9100D certifications, guaranteeing reliability in critical applications.

What truly distinguishes JXD is its role as a custom CNC machining manufacturer. Recognizing that no two projects are identical, the brand collaborates closely with clients to optimize designs for manufacturability, cost-efficiency, and performance. Whether reverse-engineering legacy parts, integrating complex geometries for fluid dynamics, or scaling production from prototypes to millions of units, JXD’s engineers turn challenges into opportunities. Customization extends to surface finishes (mirror polishing, bead blasting, or electroplating), heat treatments, and even in-house laser marking for traceability.

As a manufacturer in China, JXD leverages the country’s advanced tooling and automation sectors to deliver competitive pricing without compromising quality. The factory employs CAD/CAM simulations, in-process probing, and AI-driven quality control systems to minimize waste and rework. Yet, JXD’s cost advantage doesn’t stop at machining—the brand’s vertical integration includes in-house SUS304 coil sourcing, ensuring material traceability and consistency across batches.

For manufacturers in sectors like medical, automotive, and marine engineering, JXD’s precision stainless steel components are game-changers. A recent case study highlights a German medical device firm that reduced assembly costs by 35% after partnering with JXD to redesign a catheter hub using SUS304’s biocompatibility. Similarly, a U.S. marine equipment producer achieved NSF certification for a corrosion-resistant valve body, thanks to JXD’s expertise in passivation and salt-spray testing.

JXD’s reputation as a SUS304 stainless steel supplier is built on agility. The brand offers rapid prototyping, with samples delivered in 5–7 days for urgent projects. Custom orders undergo rigorous testing, including dimensional verification, hardness testing, and fatigue simulations, with clients receiving detailed inspection reports and 3D scan data. This transparency has earned JXD partnerships with Fortune 500 firms and startups alike, from Johnson & Johnson to clean-tech innovators.

China’s manufacturing ecosystem empowers JXD to innovate rapidly. The factory’s proximity to steel mills and logistics hubs ensures quick turnaround times for material stock and finished goods. JXD also provides value-added services, such as design for manufacturing (DFM) consultations, just-in-time (JIT) delivery, and inventory management programs, minimizing clients’ supply chain risks. For projects requiring compliance, the brand offers certifications like FDA, RoHS, and custom documentation for audits.

In an era where sustainability and precision are paramount, JXD’s solutions shine. The brand’s machines are optimized for energy efficiency, and its recycling programs reuse 98% of metal swarf. Meanwhile, its custom designs for electric vehicle battery enclosures, renewable energy components, and lab-on-a-chip devices prove that SUS304’s versatility knows no bounds.

For engineers, procurement managers, and R&D teams, JXD offers more than parts—it offers a strategic partnership. Whether you’re launching a new product, improving existing designs, or navigating supply chain disruptions, JXD’s CNC machined SUS304 parts are engineered to deliver.

In conclusion, JXD’s mission is to power industries with stainless steel solutions that are as resilient as the challenges they face. As a custom CNC machining manufacturer in China, the brand continues to push boundaries, ensuring that clients worldwide have access to technology that’s precise, sustainable, and built to last. Explore JXD’s capabilities today and discover why the world’s leading innovators trust them to machine the future—one SUS304 component at a time.