In the world of cycling, where performance hinges on millisecond advantages and material durability, precision CNC bike components have emerged as the gold standard. JXD, a leading CNC bike parts manufacturer based in China, is redefining industry benchmarks by merging advanced machining technology with a relentless focus on customization. Catering to professional racers, bike enthusiasts, and global brands, JXD’s portfolio spans everything from lightweight frame connectors to ultra-durable drivetrain parts, all engineered to elevate ride quality and reliability.

Precision CNC Bike Components: Where Engineering Meets Excellence

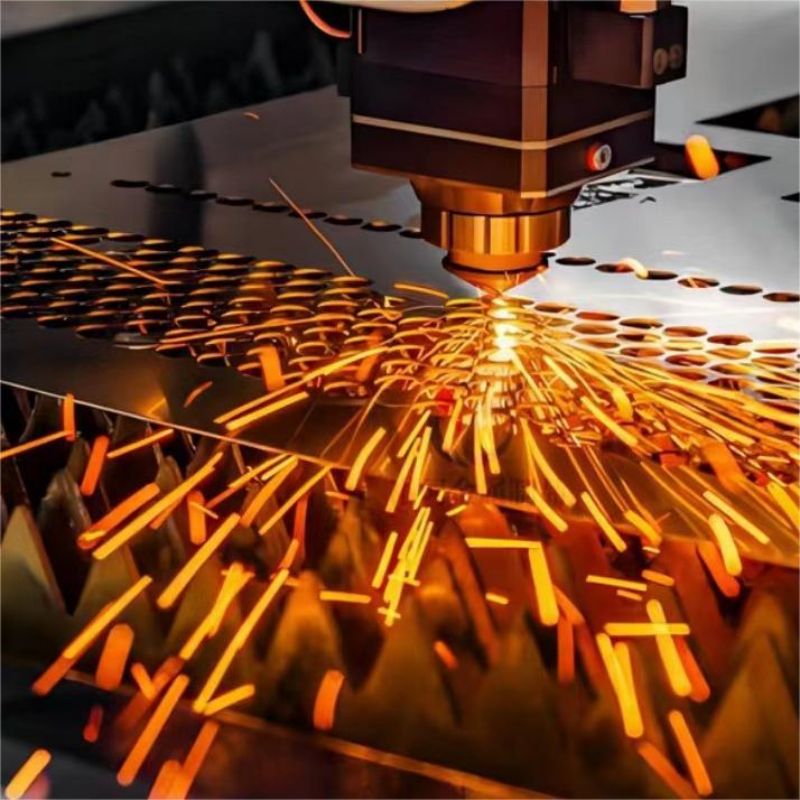

At JXD’s state-of-the-art facility, every component undergoes a rigorous journey from design to delivery. Utilizing 5-axis CNC milling and turning machines, the brand achieves tolerances as tight as ±0.005mm—a level of accuracy critical for parts like suspension pivots, derailleur hangers, and brake mounts. Unlike traditional casting or forging methods, CNC machining allows for intricate geometries and hollow structures that reduce weight without sacrificing strength. For example, JXD’s titanium seat post clamps weigh 40% less than standard aluminum versions while withstanding 1,200 kg of clamping force, a testament to their material expertise.

Custom CNC Bike Parts Supplier: Tailoring Performance to Your Needs

Understanding that no two riders or bikes are identical, JXD positions itself as a custom CNC bike parts supplier, offering end-to-end solutions for niche requirements. Whether it’s adapting a stem’s rise angle for ergonomic comfort, creating proprietary chainring tooth profiles for mud-prone terrains, or prototyping aerodynamic water bottle cages, JXD’s in-house engineering team collaborates closely with clients to translate ideas into functional prototypes within days. The brand’s rapid iteration process—powered by CAD/CAM software and on-site 3D printing—ensures that even the most complex designs, like integrated cockpit systems or modular cargo racks, meet performance and aesthetic expectations.

Why China’s JXD Stands Out Among Manufacturers

As a China-based CNC bike parts manufacturer, JXD leverages the country’s robust supply chain ecosystem and skilled labor pool to deliver cost-effective solutions without compromising quality. Their vertical integration—from raw material sourcing (including aerospace-grade aluminum 7075 and carbon fiber composites) to final anodizing or powder coating—ensures full control over production timelines and quality checks. Moreover, JXD’s adherence to international standards like ISO 9001 and CPSC safety certifications has earned them partnerships with over 50 cycling brands across Europe, North America, and Asia.

Sustainability: Machining with a Conscience

In an industry increasingly conscious of its environmental footprint, JXD prioritizes eco-friendly practices. Their CNC processes generate minimal waste compared to subtractive manufacturing, and 90% of metal chips are recycled into new billets. The brand also offers anodizing services using non-toxic dyes and promotes modular designs that extend component lifespans, reducing the need for frequent replacements.

For cyclists and manufacturers seeking precision CNC bike components that push boundaries, JXD isn’t just a supplier—it’s a collaborator in innovation. With a blend of Chinese manufacturing efficiency and bespoke engineering prowess, the brand is geared to power the next generation of high-performance bicycles.