In the high-stakes world of cycling, where every gram, watt, and millimeter counts, JXD has emerged as a trailblazer in crafting brass CNC bike parts and mountain bike components that redefine performance, durability, and design. As a leading precision bicycle parts manufacturer based in China, JXD blends cutting-edge CNC machining with a relentless focus on customization, delivering solutions that empower cyclists and brands to conquer new frontiers.

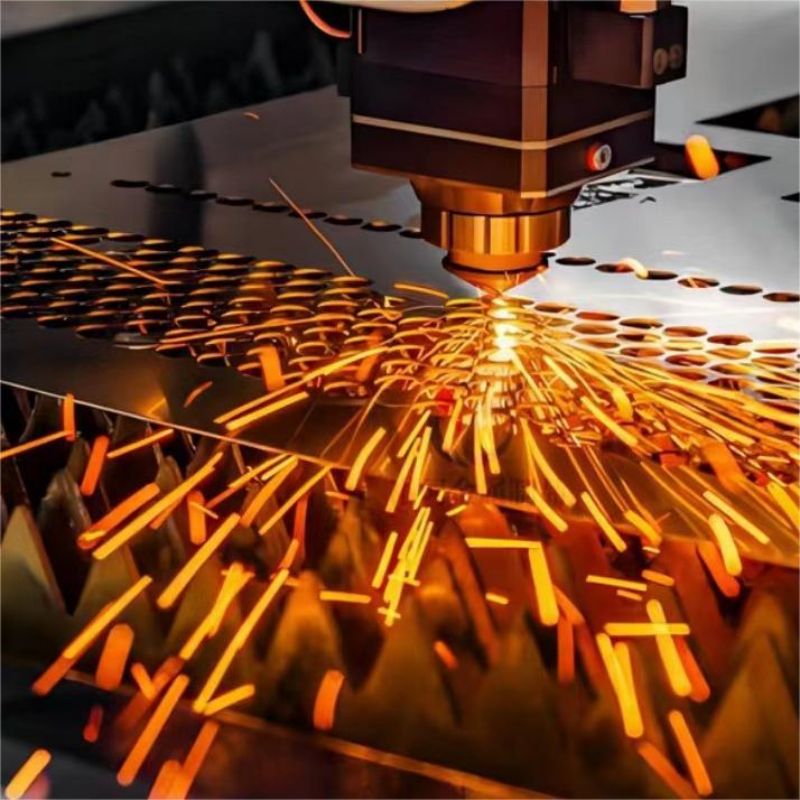

At the core of JXD’s innovation lies its brass CNC bike parts, a testament to the brand’s mastery of metallurgy and precision engineering. Brass, prized for its corrosion resistance, aesthetic appeal, and machinability, is transformed into components like derailleur hangers, bottle cages, and headset spacers that balance form and function. JXD’s 5-axis CNC milling centers achieve tolerances as tight as ±0.01mm, ensuring seamless integration with frames, drivetrains, and suspension systems. The result? Parts that not only enhance performance but also stand out with a luxurious, golden hue that sets bikes apart in a crowded market.

For mountain bikers demanding rugged reliability, JXD’s mountain bike components are engineered to endure the harshest terrains. From lightweight aluminum chainrings and titanium pivot bolts to adjustable dropout reinforcements, every component is optimized for strength-to-weight ratios, impact resistance, and fatigue life. JXD’s use of advanced finite element analysis (FEA) simulates real-world stressors, allowing engineers to refine designs before production—a process that slashes development timelines and ensures flawless performance in enduro races, downhill thrills, or epic backcountry adventures.

What truly distinguishes JXD is its role as a custom CNC machined bike components supplier. Recognizing that cyclists and brands crave uniqueness, JXD’s in-house design team collaborates with clients to turn wild ideas into reality. Whether it’s etching custom logos into brake levers, crafting one-off stem designs, or producing limited-edition titanium bottle openers, JXD’s CNC expertise transforms visions into tangible, ride-ready parts. The brand’s agile manufacturing processes accommodate low-volume orders, making elite-level customization accessible to pro teams, boutique builders, and passionate enthusiasts alike.

China’s manufacturing prowess is the backbone of JXD’s capabilities. The brand’s ISO 9001-certified facilities house state-of-the-art Haas and DMG Mori CNC lathes, robotic polishing stations, and anodizing lines, enabling end-to-end control over quality, lead times, and costs. From raw brass billets to finished components, every step adheres to strict protocols, ensuring parts that meet or exceed UCI, EN, and ASTM standards.

For eco-conscious cyclists, JXD offers sustainable options, including recycled brass alloys, water-based cutting fluids, and zero-waste machining practices. The brand also provides refurbishment services for worn parts, extending their lifespan and reducing environmental impact—a nod to the cycling community’s values of stewardship and sustainability.

In an industry where innovation never sleeps, JXD’s commitment to R&D is unwavering. The brand partners with professional athletes, material scientists, and design studios to pioneer technologies like self-lubricating bushings, vibration-damping titanium alloys, and modular component systems that adapt to evolving riding styles.

Whether you’re a World Cup downhiller seeking a competitive edge, a frame builder crafting heirloom-quality bicycles, or a rider simply tired of off-the-shelf parts, JXD delivers—where every spindle is spun for speed, and every curve is carved for custom artistry.

In a world where bikes are more than machines—they’re extensions of the rider—JXD stands as a trusted ally, empowering two-wheeled pioneers to ride faster, farther, and with unmatched style. Trust in JXD—where every component is a masterpiece of precision, and every partnership is a ride toward perfection.